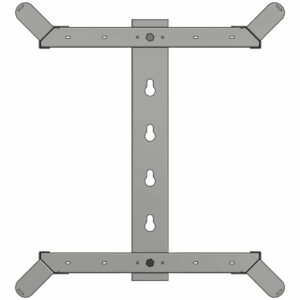

Redesigning the H-Frame Fiber Storage System for Performance, Cost Efficiency & Scalable Production

Introduction

American Products partnered with a major telecommunications customer to re-engineer a strand-mounted H-Frame fiber storage solution that would enhance capacity, improve manufacturability, reduce total cost, and streamline field installation. Through our proactive design process, engineering expertise, and in-house manufacturing capabilities, we delivered a highly efficient, scalable solution that exceeded customer expectations—and opened the door for further product innovation.

Background Information

The customer had been using a competitive fiber storage frame but was experiencing multiple challenges related to capacity, packaging, field use, and long-term costs. American Products was asked to assess the design and identify opportunities to improve performance while aligning the product with our scalable, cost-effective manufacturing processes.

Our engineering team conducted a detailed review of the existing design, product requirements, and operational constraints, then initiated a full redesign cycle using standard fabrication methods to validate concepts before moving into advanced tooling and mass-production optimization.

Problem Statement

The customer desired a redesigned H-Frame that addressed several limitations of their existing product:

- Poor fiber hook design and limited fiber storage capacity

- Oversized packaging that increased shipping costs and consumed excess inventory space

- High initial product cost and long-term cost concerns

- Low production throughput and long lead times due to inefficient fabrication methods

Additionally, after proving the initial redesign, the customer requested an enhanced version capable of storing fiber on the stand with a single access point, eliminating the need to over-lash or de-lash during maintenance.

The Solution

Phase 1: Product Redesign for Performance & Manufacturability

American Products engineered a new H-Frame design incorporating:

- Greater fiber storage capacity

- Improved hook geometry for cleaner cable management

- Modular field assembly, enabling multiple units per package to reduce pallet space and shipping costs

- Optimized manufacturing features that align with our in-house processes

- Cost-matched design that maintained customer pricing targets despite better performance

Using standard fabrication methods, we built initial units to validate:

- Mechanical strength

- Fiber capacity

- Field handling

- Production flow and volume estimates

This phase confirmed the design direction and allowed us to predict volume scalability.

Phase 2: Investment in Hard Tooling for High-Volume Production

Once volumes were confirmed, American Products invested in dedicated stamping press tooling, enabling:

- Unlimited manufacturing capacity

- Significant reductions in labor and machine time

- Consistent part quality across large batches

- Ability to absorb triple-digit raw material cost increases without passing cost increases to the customer

This upgrade directly supported the customer’s need for higher throughput and reduced lead times.

Phase 3: Development of an Advanced Fiber Storage Frame

The customer then requested an improved version capable of storing fiber at a single location on the strand without de-lashing. American Products engineered a new concept featuring:

- 8" height compatible with 12" strand spacing requirements

- Storage capacity of over 150 ft of fiber on a single unit

- Offset strand-mounted bracket for easy installation and maintenance

- No de-lashing required for re-access or re-lashing

The new model entered field testing soon after initial prototyping.

Results

The contrast between the old and new websites demonstrates the power of strategic design and platform migration:

Design & Functional Improvement

- Increased fiber storage capacity

- Enhanced hook geometry and cable control

- Faster, simpler field assembly

- Single-point access eliminates over-lashing and improves technician efficiency

Cost & Operational Benefits

- Reduced shipping cost through optimized packaging

- Lower inventory space requirements

- No price increases despite major raw material inflation—made possible by stamping press automation

- Higher production capacity with shorter lead times

Customer Impact

- Ability to deploy more units per job site

- Reduced labor time and installation complexity

- Improved long-term cost predictability

- A more durable, optimized product aligned with real-world telecom infrastructure needs

Conclusion

This H-Frame redesign showcases American Products’ proactive engineering capabilities and commitment to delivering solutions that align with customer needs, manufacturing efficiency, and long-term cost control. By blending practical field input with innovative design and high-capacity U.S. manufacturing, we transformed a competitive design into a superior, scalable fiber management solution.

The success of this project also led to a second-generation product, demonstrating our ability to evolve alongside our customers and continuously deliver meaningful improvements in the telecommunications sector.

Request a Custom Quote

Need a custom-built enclosure or H-Frame solution?

Tell us about your project and our team will get back to you with a tailored recommendation.